Product

Bridge production line

Classification: Production line products

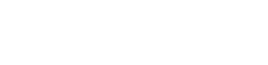

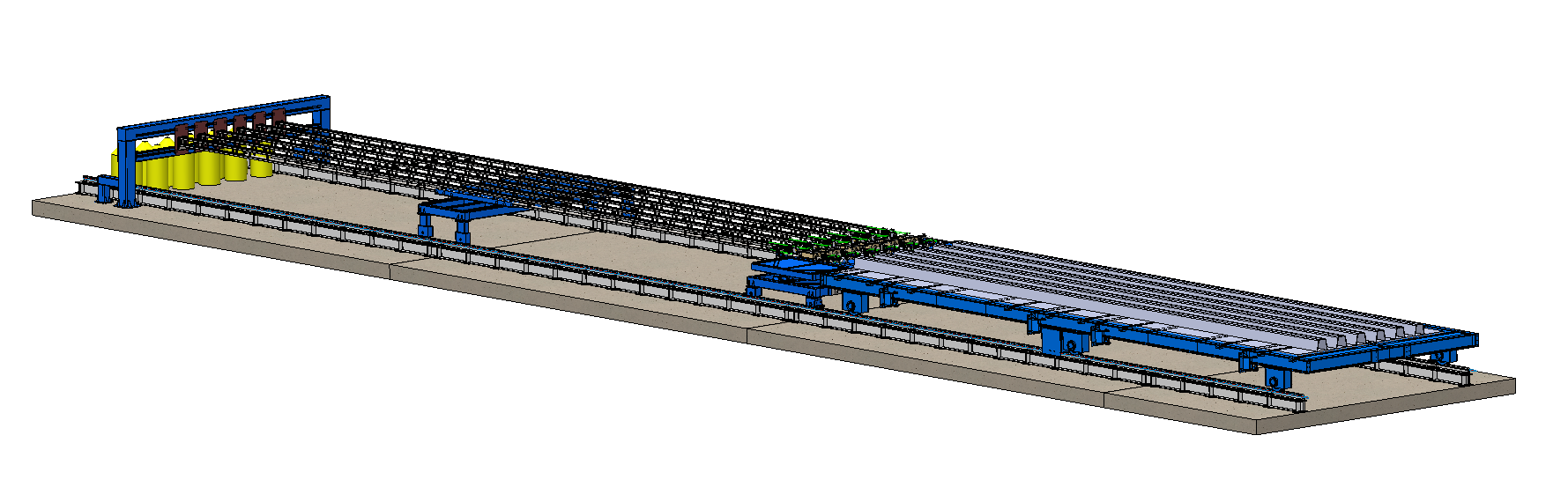

The bridge production line mainly consists of multi-head U-rib internal welding machine, multi-head U-rib external welding machine and anti-deformation tire frame.

Product Introduction

Bridge production line

The bridge production line mainly consists of multi-head U-rib internal welding machine, multi-head U-rib external welding machine and anti-deformation tire frame.

1.Multi-head U-rib internal welding machine

Equipment Introduction:

U-rib submerged arc welding internal seam special machine is a special equipment for simultaneous welding of internal seams between multiple U-ribs and base plate of plate unit.

The U-rib submerged arc welding machine is mainly composed of fine wire submerged arc welding head, head connecting arm, welding traveling cart and spacing adjustment mechanism, wire feeding mechanism, welding seam tracking mechanism and electrical control.

Main features:

Ø High welding efficiency: U-ribbed plate is welded by multiple heads at the same time; the mechanical automatic tracking of weld seams reduces labor costs.

Ø Highly integrated manipulation system: the manipulation system integrates the motion control of welding traveling cart and welding control with one body, which can be operated by wireless remote control, and the operation is convenient and flexible, with a high degree of automation.

Ø Cost saving: Using Huayuan inverter technology welding machine can save 25-35% of electricity consumption.

Ø Stable operation of the equipment: the welding traveling cart adopts bilateral drive and travels smoothly.

Ø Intelligent module options: support IOT data acquisition, support MES management software data docking.

2.Multi-head U-rib external welding machine

Equipment introduction:

U-rib submerged arc welding outside seam special machine is specialized in welding outside seam of butt joint between plate unit U-rib, plate rib and base plate. The weld seam is turned over and adjusted to the ship shape position by turning the tire frame, and the special machine can weld several U-rib outer seams at the same time.

U-rib submerged arc welding outer seam special machine mainly consists of gantry frame, traveling drive mechanism, guide column traversing mechanism, guide column lifting mechanism, weld laser tracking system, welding power supply, electrical control system and so on.

Main features:

Ø High welding efficiency: U-ribbed plate is welded by multiple heads at the same time; laser automatically tracks the weld seam, reducing labor cost.

Ø Highly integrated manipulation system: the manipulation system integrates the gantry motion control and welding control into one, which can be operated online and by wireless remote control, and the operation is convenient and flexible, with a high degree of automation.

Ø Labor saving: Based on the highly integrated control system, the operation configuration can be done by 1-2 persons.

Ø Saving cost: by choosing Huayuan inverter technology welding machine, it can save 25-35% of electricity consumption.

Ø Stable operation of equipment: the gantry traveling adopts bilateral drive, traveling smoothly.

Ø Intelligent module option: support IOT data collection, support MES management software data docking.

3.Anti-deformation tire rack

Equipment introduction:

- rib anti-deformation tire rack is used to realize the balance of the thermal deformation generated by the bridge plate welding and realize the workpiece tilted to a certain angle of the ship position welding, in order to achieve the welding requirements of the special auxiliary equipment.

Main features:

Ø High integration of anti-deformation tire frame, compact design and beautiful appearance.

Ø The whole adopts hydraulic way to realize workpiece pressing, aligning and turning.

Ø Hydraulic oil circuit adopts self-locking method to increase safety and reduce energy consumption.

Keywords:

Bridge production line

Immediate Consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!